Infrastructure

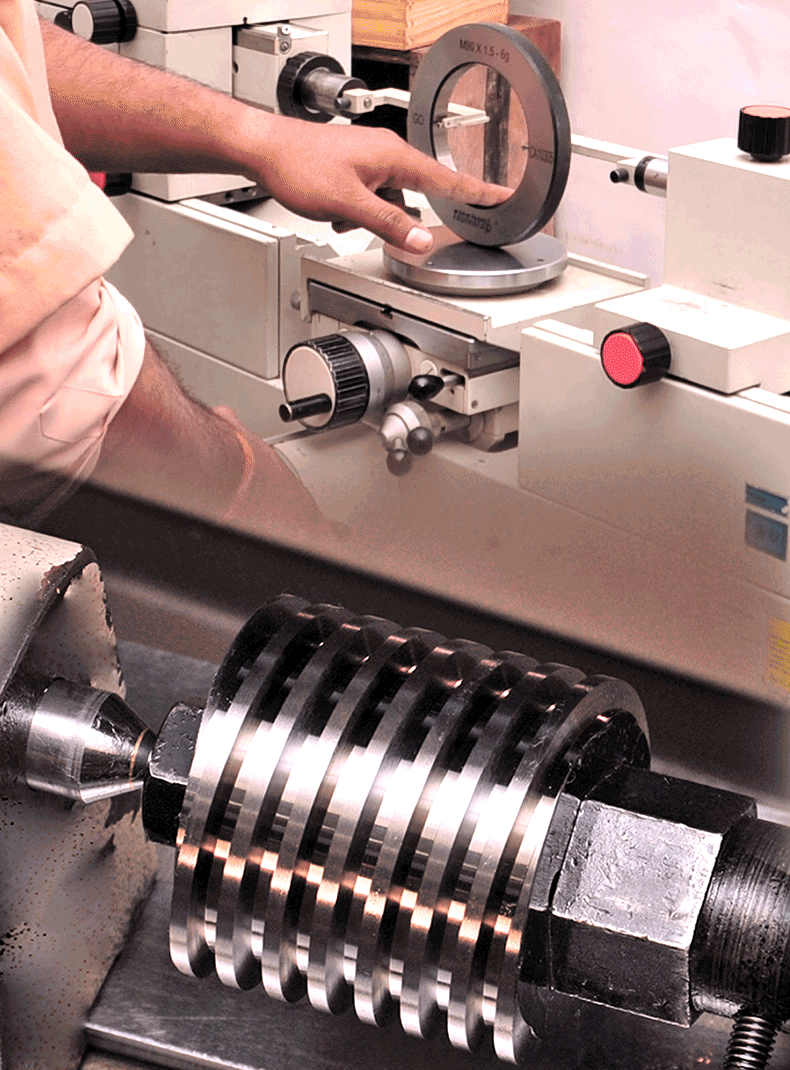

Tru-Thread has built a modern Manufacturing & calibration facilities required to manufacturer consistent Quality Gauges.

Our manufacturing plant is spread over 5000 sq.meters area. This is an environment freindly Green facility with rain water harvesting & electricity generation with roof top solar Panels. The manufacturing facilities comprise of CNC & NC machines sourced from the world leaders in machine Tools like Matrix,UK, Reishauer,Switzerland.

We have in-house Heat Treatment facility. Our calibration lab is equipped with instruments sourced from Zeiss-Germany, trimos-Switzerland, Mitutoyo-Japan

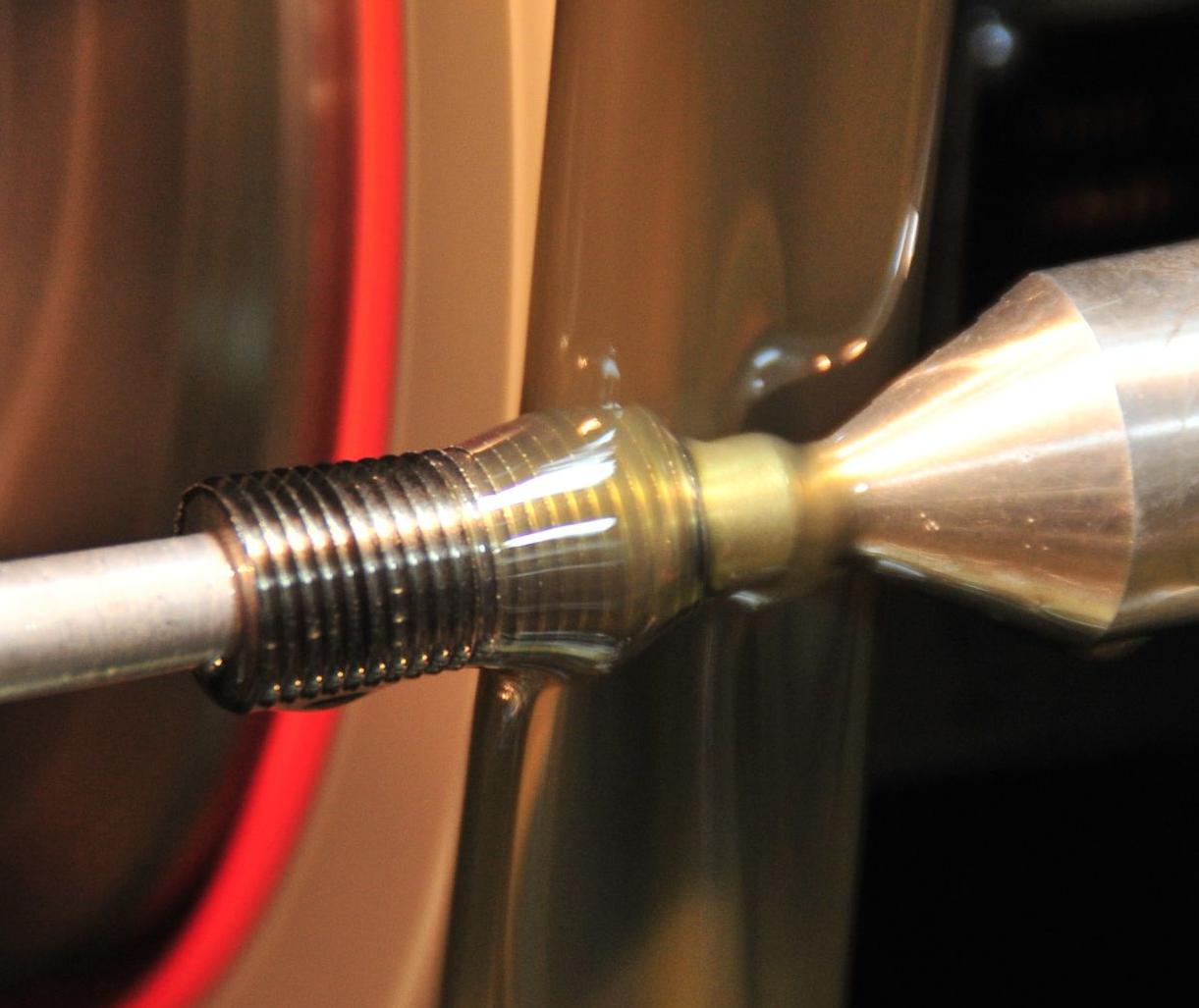

MANUFACTURING

We extensively use modern machine Tools with CNC/NC technologies for manufacturing. All-important manufacturing activities are done in-house. This gives us full control over product quality.

Our every manufactured product is subject to in-process & Final Inspection & is uniquely identified for traceability.

Discover

HEAT TREATMENT

We use atmosphere-controlled electrical furnaces for heat treatment. As the furnaces are electrical, they offer excellent & precise control of the Heat treatment cycle. With the electronic controlling & recording system, the heat treatment cycle is mapped & recorded.

The heat treatment cycle is periodically validated to maintain the consistency of the micro-structure.

Discover